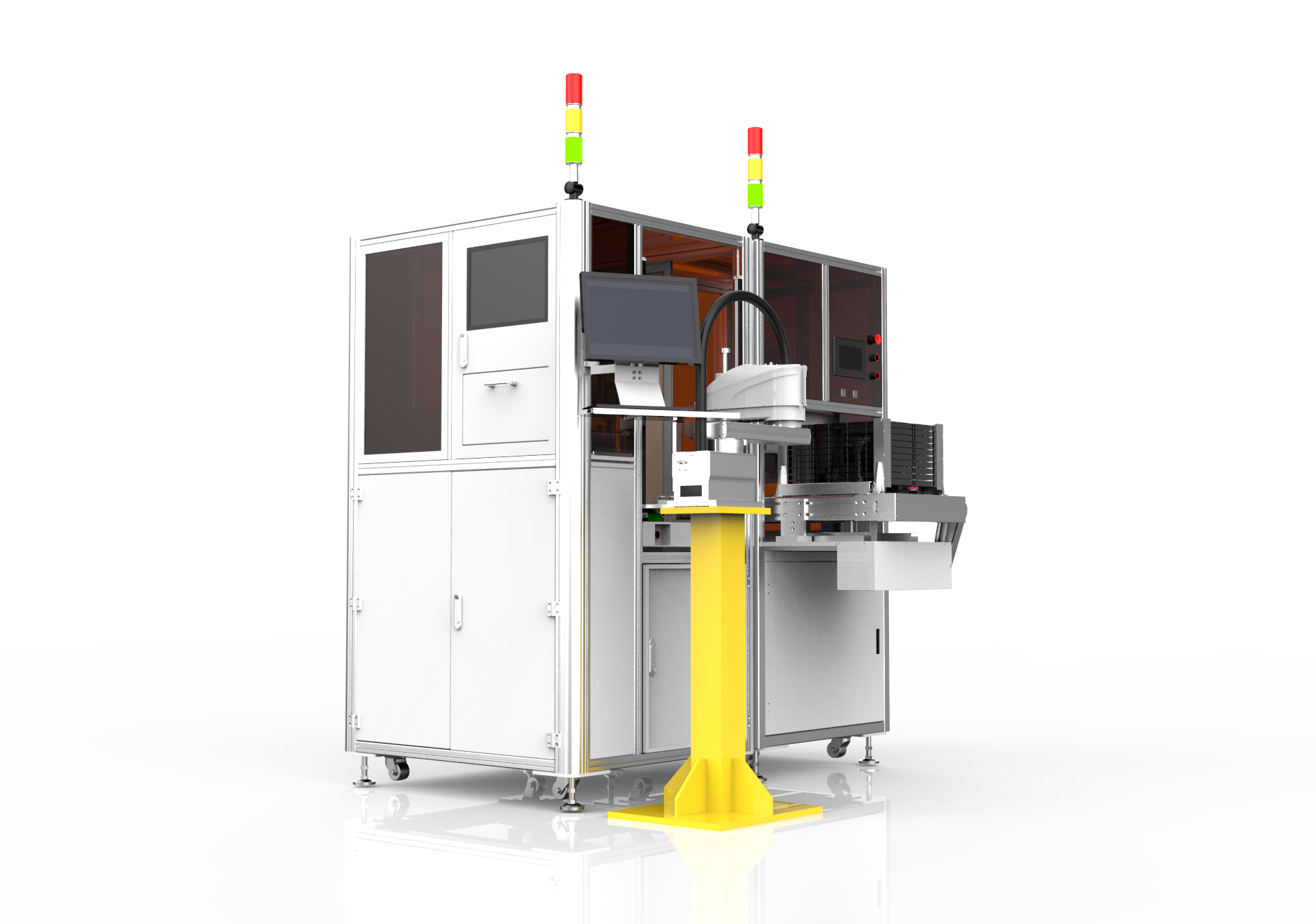

What is the purpose of the multi station all in one machine for dispensing solder detection

source:m.asuszp.com.cn | Release time:2025年04月09日1. dispensing function

Correct application: the glue can be correctly applied to a certain position, such as the pins of electronic components, specific areas of circuit boards, etc., to ensure that the amount of glue is correct and evenly distributed, meet the dispensing process requirements of different products, and improve the stability and reliability of products.

Application of various glues: it can adapt to various types of glues, such as epoxy resin adhesive, silica gel, hot-melt adhesive, etc., and is applicable to the bonding requirements of different materials. It is widely used in the product assembly process of electronic, automotive, medical and other industries.

2. soldering function

Welding electronic components: used to weld electronic components to the circuit board to achieve electrical connection. By correctly controlling the temperature, time and amount of solder, the welding quality can be guaranteed, the welding defects such as false soldering and short circuit can be reduced, and the performance and stability of the circuit board can be improved.

Adapt to different welding scenarios: welding operations can be carried out for different types of electronic components and circuit board layouts. Whether plug-in components or surface mount components, efficient and correct welding can be achieved to meet the production needs of various electronic products.

3. detection function

Appearance inspection: the visual inspection system is used to inspect the appearance of the product, such as checking whether the dispensing is uniform, whether the solder is full, whether the components are installed in place, etc., which can quickly find the defects and flaws on the product surface, timely eliminate the unqualified products, and improve the overall quality of the product.

Dimension measurement: measure the key dimensions of the product, such as the size of the solder joint, the width of the glue dispensing, etc., to ensure that the size of the product meets the design requirements, which helps to ensure the consistency and interchangeability of the product.

Electrical performance test: some all-in-one machines also have the function of electrical performance test, which can carry out power on test on the welded circuit board to detect whether the circuit conductivity, resistance, capacitance and other parameters are normal, so as to find potential electrical faults in time and improve the qualification rate of products.

4. multi station integration

Improve production efficiency: multiple processes such as dispensing, soldering and testing are integrated on one equipment, realizing automatic multi station operation. Products automatically flow between different stations, reducing the time of manual handling and loading and unloading, greatly improving production efficiency and reducing production costs.

Ensure the stability of product quality: since the whole production process is completed on one equipment, the error and uncertainty caused by manual operation and equipment switching are reduced, which can better ensure the stability and consistency of product quality, and is conducive to large-scale production and quality control.

To sum up, through integrating various functions, the multi station all-in-one machine for dispensing and soldering tin detection has realized a one-stop production process from dispensing, soldering tin to detection, which is widely used in electronic manufacturing and other industries, helping to improve production efficiency, reduce costs and improve product quality.

prev:

What are the characteristics of the sealing vacuu…

next:

What is the double tube precision screw valve glu…

中文

中文 英文

英文

WeChat official account

WeChat official account

Scan your phone once

Scan your phone once

Wechat ID:

Wechat ID:

wechat

wechat

contact

contact

phone

phone